When making custom molds and components, quality is of utmost importance. But these quality molds have to retain their tip-top shape from the moment they are fresh out of the factory until they are delivered to customers. Let’s get into the details of the packaging and delivery essentials for custom precision molds.

Custom precision molds, tools, and components have a significant role in the manufacturing industry as they help in the production of complex products with intricate details. These molds are used in various industries, such as automotive, medical, aerospace, electronics and connectors. The high demand for precision molds has resulted in a competitive market in the niche, where manufacturers are striving to produce quality molds that meet their customers’ specifications.

If you are somehow associated with the precision industry, you will know that QC and testing are of the utmost importance. As a custom precision tool and mold maker, it is not just about exacting the engineering specifications set by the customer but also the desired packaging standards for a smooth and hassle-free delivery.

A well-defined packaging and delivery process will help ensure that the precision molds and parts reach their destination safely and intact. Manufacturers must define protocols and implement best practices to ensure that their molds are packaged correctly and delivered on time. This blog will explain how packaging has to be done and the delivery norms to be taken into account when dealing with custom precision molds, tools, and their components to ensure they reach the end users in optimal condition.

Desirable Packaging Process for Your Custom Precision Molds

In the manufacturing industry, the importance of custom precision molds is undeniably present. They are used to produce various products such as automotive parts, medical devices, and electronic components. Vietnam has become a hub for custom precision mold manufacturing, and designing the packaging for these molds is crucial for their protection during transportation. Packaging design can influence the quality and integrity of the molds, and even minute flaws can ruin the efforts of the rigorous production process.

At times, damage during transit can be costly for manufacturers, leading to unwanted delays and additional expenses. Thus, it is crucial to have a packaging process that can safeguard your custom precision molds. As a manufacturer, you cannot afford to overlook the packaging process.

1. Demagnetizing

Before packaging precision molds and their components, demagnetization is highly recommended. Precision molds are susceptible to magnetization due to the use of magnetic materials during their manufacturing process. This magnetization can cause the molds to attract unwanted metal debris during the packaging and shipping process. To prevent this, precision molds must undergo a demagnetizing process. This process involves exposing the molds to a demagnetizing field that will neutralize any magnetic charge.

That’s why it’s essential to include demagnetization procedures to ensure the molds are free from any magnetic interference. By taking this important step, you can ensure that your custom precision molds will produce high-quality products every time.

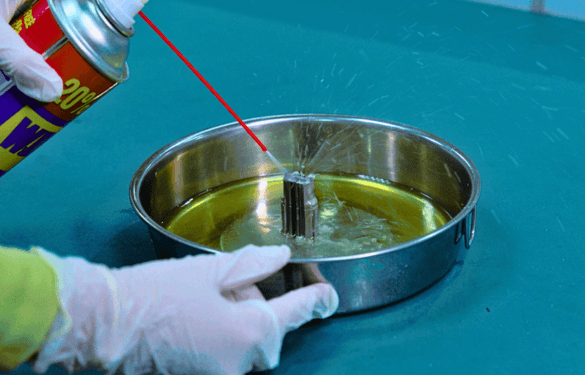

2. Rust-proofing

Rust-proofing is a key aspect to take into account when packaging custom precision molds. Rust can cause serious damage to the mold, compromising its accuracy and functionality. To prevent this, precision molds are typically coated with rust inhibitors before being packaged and shipped. The rust inhibitors create a barrier that protects the molds from moisture and other environmental factors that can cause rust to form.

By taking the time and effort to rust-proof the packaging, you can ensure that your custom precision molds arrive at their destination in top-notch condition, ready to deliver the highest quality products. So, don’t cut corners on rust-proofing; it’s a small investment that can make a big difference in the long run.

3. Protective Wrapping

1. CNCTech

2. CAM Resources

CAM Resources has the right precision EDM, wire-cutting, grinding machines that can meet customer’s exact engineering specifications. As proof of the company’s excellent work in the industry, CAM Resources is the first foreign company to be awarded the Certificate of Science & Technology Enterprise by the People’s Committee of Long An Province.

CAM Resources also offers worldwide shipping of finished products in a timely and hassle-free fashion. It is one of the best choices for clients who are looking for surface grinding service that inherits foreign technology for a competitive pricing plan.

Protective wrapping plays a special role in designing packaging for custom precision molds. This thin layer wrap offers extra protection so that the molds arrive at their destination in perfect condition. Whether you’re shipping the molds across the country or just down the street, packaging that is designed with protective wrapping can help prevent damage during transport.

This is especially important when dealing with precision molds, which require careful handling and protection from any bumps or jostles. By taking the time to include protective wrapping in your packaging design, you can help ensure that your custom precision molds arrive safely and securely, ready to be put to use in their new home.

4. Packaging Materials

When it comes to packaging custom precision molds, there are a variety of materials that are commonly used. These materials serve different purposes and offer various levels of protection for the molds. Some of the most popular materials include styrofoam, plastic, and cardboard.

Styrofoam is great for protecting the molds during transport, as it can absorb shock and prevent any damage. Plastic, on the other hand, is durable and can withstand harsh conditions. Lastly, cardboard is an eco-friendly option that provides a cost-effective solution while also protecting the molds from scratches and other damages. Each of these materials has its benefits and drawbacks, so it’s important to choose the right packaging material based on your specific needs.

While designing the packaging process for custom precision molds, manufacturers have to carefully consider several aspects discussed above. Good packaging standards should be able to protect the molds during transportation to ensure their integrity and quality, so they reach their destination in perfect condition and are ready for use in the production process.

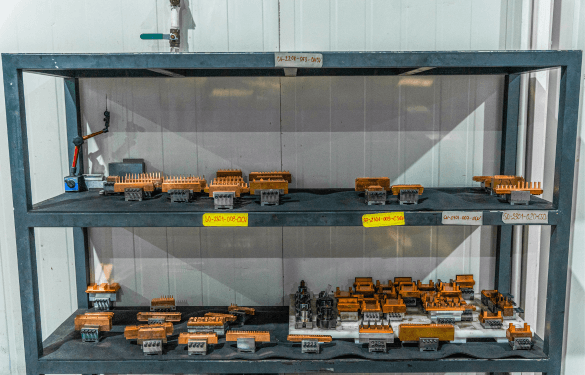

Labeling the Custom Precision Mold Packages

Proper labeling plays a significant role in ensuring that custom precision molds are packaged and delivered correctly. Each mold is unique and requires specific handling instructions to prevent damage during transportation. The importance of proper labeling does not end with packaging. With the labeling done right, the package can be prioritized and handled with care, and any delays or confusion can be avoided pre- and mid-shipping.

1. Why Proper Labeling is Needed for Custom Precision Molds

Proper labeling in the packaging and delivery of custom precision molds is crucial for ensuring that these valuable items are handled with care and arrive at their destination safely. Labels that indicate the contents of the package, as well as any special handling instructions, can help prevent damage or mishandling during shipping.

In addition, proper labeling also ensures that the recipient knows exactly what they are receiving, which can be particularly important when dealing with custom precision molds that may have unique specifications or requirements. Overall, taking the time to label packages correctly can help ensure that custom precision molds arrive at their destination in good condition and that all parties involved are fully informed and prepared for handling them.

2. What Information Needs to Be On the Label

When it comes to labeling products, it’s important to include certain types of information. For custom precision molds, the label should include the name of the manufacturer, the type of mold, and the date it was created. This information helps ensure that the mold is being used correctly and safely.

Additionally, the label should include any special guidelines or instructions for use. This could include information on how to properly clean and maintain the mold as well as any safety precautions that need to be taken when handling it. Overall, a clear and informative labeling system is crucial for ensuring that custom precision molds are used correctly and safely.

3. How Proper Labeling can Help Avoid Complications in Delivery

Proper labeling is crucial when it comes to avoiding complications during delivery. When items are labeled correctly, it makes it easier for the delivery team to identify and sort packages quickly and efficiently. This not only saves time but also reduces the chances of errors occurring during the delivery process.

For example, custom precision molds are delicate items that require special care during transit. By labeling them properly, the delivery team can ensure that they are handled with the necessary precautions. When packages are not labeled correctly, it can lead to delays, damages, and even lost items.

Choosing the Professional Shipping Partner to Deliver Custom Precision Molds

Proper labeling is essential, but it is equally important to work with a reliable shipping company that has experience handling custom precision molds and can provide the necessary packaging materials and transportation methods to ensure safe delivery. Additionally, they can also offer insurance coverage to protect against any damage or loss during transit.

This is crucial because any damage or imperfections during transport can compromise the integrity of the molds and ultimately affect the final product. Plus, timely delivery is essential to keeping your production schedule on track and meeting your customers’ needs. So, make sure to choose a delivery service that is reliable and experienced in handling delicate and valuable items like custom precision molds.

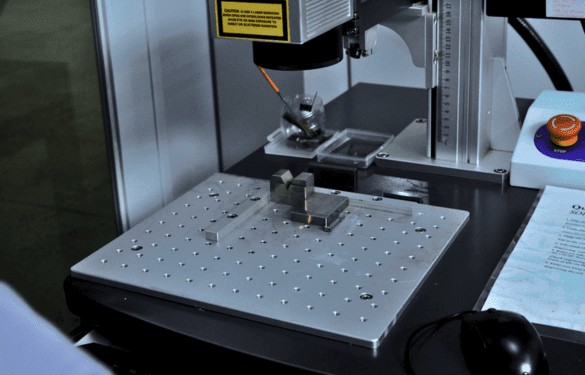

Ordering custom precision molds from CAM Resources

When it comes to custom precision molds, CAM Resources is the way to go! Not just make highly accurate precision molds that are put through rigorous testing processes, but we also take our packaging and delivery processes seriously, ensuring that each mold is demagnetized, rust-proofed, labeled, and wrapped with protective material. Furthermore, we offer custom laser marking services for customers upon request. And don’t worry about getting your package on time. Our reliable logistics partner, DHL, will make sure it gets to your doorstep safely and promptly.

But that’s not all! CAM Resources prides itself on our exceptional customer service. With a dedicated and diverse workforce that speaks six different languages, including Vietnamese, English, Japanese, Chinese, Korean, and Hindi, we are more than equipped to help you with any questions or concerns you may have. With CAM Resources, you and your custom precision molds specifications are in good hands.

So get in touch with us today to get your order in!