Manual surface grinding and…. automatic surface grinding? What are they, and which is a better fit for your business? This blog will offer you some info so that you can understand more about the two types, and make the best choice!

Need surface grinding for your business? Yes, we are talking about mold, jig and die components! You did the research, found the list of manufacturers you liked, but then you also stumbled upon the terms “manual” and “automatic” which confused you.

As a manufacturer or business owner, you know that surface grinding is a critical process in producing high-quality products. But when it comes to types of surface grinding, one of the most significant decisions you’ll have to make is whether to go with a manual or automatic approach. Both methods have their pros and cons, and choosing the right one can make all the difference in the quality of your finished products. We are living in the age of automatization, so what’s with all the need for manual, anyways?

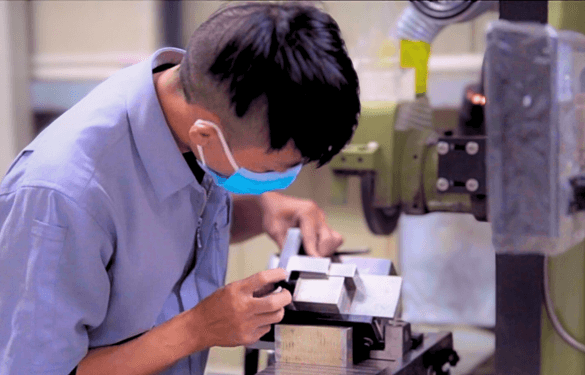

Manual surface grinding is the traditional method that has been used for decades. It involves a skilled operator using a hand-held grinder to precisely shape and finish the surface of a workpiece. On the other hand, automatic surface grinding process is a modern approach that utilizes computer-controlled machines to perform the same tasks with greater speed and accuracy. But which approach is better for your business? Let’s buckle up and explore the differences between the two methods, so you can make an informed decision that will benefit your bottom line.

Definition of surface grinding

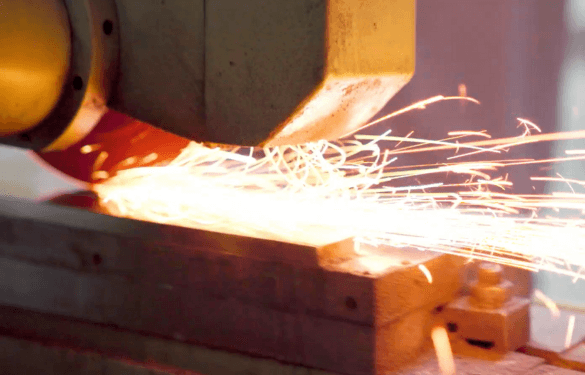

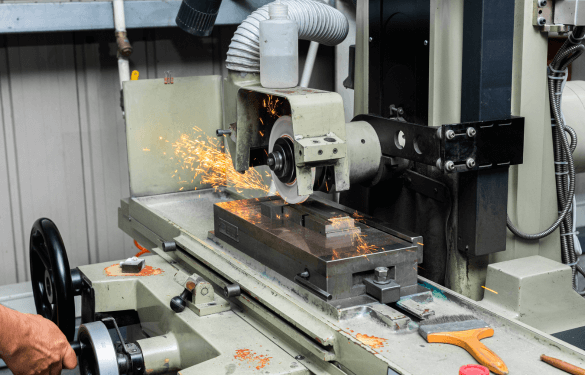

Surface grinding is a process that involves the use of a grinding wheel to create a smooth and flat surface on a material. This is often done on metal surfaces, but can also be used on other materials such as ceramics and plastics. The process involves the use of a rotating grinding wheel that grinds the surface of the material until it is smooth and flat.

Surface grinding is commonly used in the manufacturing industry to create precision parts for machines and other equipment. It is also used in the automotive industry to create smooth and flat surfaces on engine parts. Overall, surface grinding is a versatile process that can be used in a variety of industries to create high-quality, precision parts.

What are surface grinding machines?

Surface grinding machines are powerful tools used in the manufacturing industry to grind and smooth the surfaces of materials. These machines use abrasive wheels to remove small amounts of material from the surface of the workpiece until it is perfectly flat and smooth. Surface grinding is a precision process that requires skill and expertise to achieve the desired result.

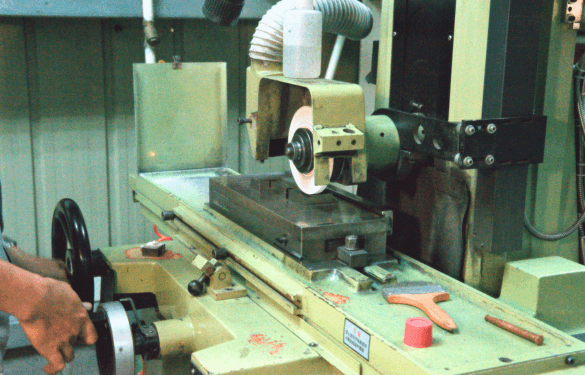

The machines come in different sizes and shapes, and they can be operated manually or with computer numerical control (CNC) technology. Surface grinding machines are used to create high-quality finishes on a variety of materials, including metal, plastic, and wood. They are essential tools for anyone who needs to create precise, smooth surfaces on their workpieces.

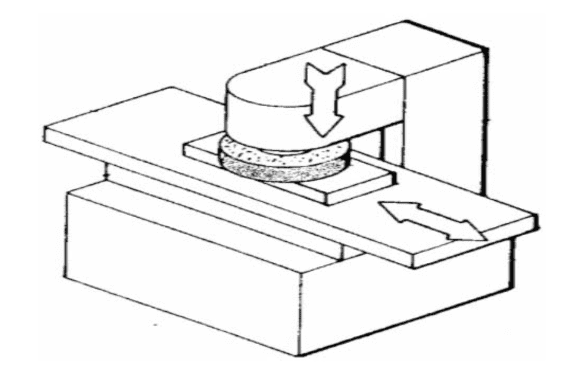

The main components of a surface grinding machine include:

- The wheel against which the workpiece will be grinded

- The chuck that is a type of clamp used to hold a workpiece in place

- The rotary table which moves the workpiece across the wheel in multiple directions

Manual versus Automatic - What’s different?

There are two types of surface grinders: manual and automatic. Manual surface grinders are operated by a person, while automatic surface grinders are controlled by a machine.

The main difference between the two is that manual surface grinders require more effort and skill to use, while automatic surface grinders are easier and faster. Manual surface grinders are best for small jobs, while automatic surface grinders are better suited for larger jobs that require quantity and speed.

1. CNCTech

2. CAM Resources

Another difference is in the way the grinding is performed. In manual grinding, the operator has to run the table with one hand, while feeding the wheel with the other. In automatic grinding, both procedures are done automatically.

While automatic surface grinding is a cost-effective solution to mass manufacturing identical parts, manual surface grinding is better when the workpieces have a complex or unique shape. The latter requires highly-skilled operators to handle the parts with care, thus taking more time to complete the process. In other words, manual surface grinders are a good choice for those who want to save money, while automatic surface grinders are a good choice for those who want to save time and increase efficiency.

CAM Resources has the right precision EDM, wire-cutting, grinding machines that can meet customer’s exact engineering specifications. As proof of the company’s excellent work in the industry, CAM Resources is the first foreign company to be awarded the Certificate of Science & Technology Enterprise by the People’s Committee of Long An Province.

CAM Resources also offers worldwide shipping of finished products in a timely and hassle-free fashion. It is one of the best choices for clients who are looking for surface grinding service that inherits foreign technology for a competitive pricing plan.

Choosing between the two types of grinders

Automatic surface grinders use computer-controlled technology to grind surfaces efficiently and precisely. In contrast, manual surface grinders require an operator to move the workpiece manually across the grinding wheel. Let’s evaluate:

Manual surface grinder

On the plus side, manual surface grinding machines offers greater control over the process, and it’s typically less expensive and easier to maintain than the other method. Additionally, manual grinders are often the best option for complex tasks that require a more personalized touch. It’s perfect for smaller jobs that need accuracy powered by the human touch.

However, there are also some downsides to manual grinding. It can be slower and require experience from the machine handler, and the results may be less consistent. Furthermore, manual grinders often have limited capacity, which can be a drawback for larger projects. Ultimately, whether manual surface grinding is the right choice depends on your specific needs and priorities.

Automatic surface grinder

On the other hand, automatic surface grinding machine process has its pros and cons too. One major advantage is that it’s much faster and requires less effort than manual grinding. The consistency is also much higher, and the capacity is greater, making it ideal for larger projects. However, there are also some drawbacks to automatic surface grinding.

One major setback however is the lack of control. This can make it difficult to achieve the desired result, especially for more complex tasks. Additionally, the higher cost and increased maintenance requirements may make it less practical for some applications. Overall, automatic surface grinding can be a great tool, but it’s important to carefully consider the advantages and disadvantages before deciding whether it’s the right choice for your needs.

Making the decision

Manual surface grinding is often preferred for smaller jobs or when precision is required. For example, if you need to grind a small piece of metal with special specifications and low tolerances, manual grinding will do just fine. This method is great for those on a low budget who still need high precision.

On the other hand, if you’re dealing with large-scale production, standard workpieces, a larger surface area, or tougher materials, automatic surface grinding machines is the best option. For instance, if you work in a factory and need to grind metal parts for a car engine, an automatic surface grinder will save you time and effort. Although it requires a higher budget, it offers high efficiency and can save lots of time. So, whether you choose automatic or manual surface grinding, it all depends on the job at hand and your specific needs.

So, making a decision is just beyond choosing between skilled operators and computerized controls. It depends on the level of precision and consistency to be achieved. While manual grinding can be effective, it is much more time-consuming and prone to human error, whereas automatic grinding is much faster and can produce parts in incredible quantities. Ultimately, the choice will depend on the specific needs of your project, the order quantity, and your budget.

If you’re looking for a grinder to suit your needs, there are a few important things to consider. For starters, think about whether you want an automatic surface grinder or a manual one. An automatic surface grinder is great if you’re looking for mass production and consistency, as it uses computerized controls to ensure accuracy. Additionally, consider the size of the grinder and its power source, as both can impact its performance. Ultimately, the right grinder for you will depend on your specific needs and preferences, so take the time to do your research and choose wisely.

Surface Grinding at CAM Resources

Many manufacturers in Vietnam and several other countries use automatic surface grinding machines because it’s fast and less labor-intensive. But at CAM Resources, all our surface grinding is performed manually and challenges a diverse range of precision custom molds and tooling parts. Precision manufacturing at CAM Resources is about getting down to the smallest digit right out of the magic hands of our skilled technicians.

Surface grinding is more of an art and the personnel in charge of these manual machines are highly experienced, and have a good understanding of the shapes and designs knowing how to achieve fine engineering tolerances. Furthermore, these machine operators’ skills are upgraded with in-house training in our well-equipped factories. For assured precision on your tools, molds, and dies, contact us now!