Explore the world of EDM technology, a highly precise and efficient manufacturing technique used in precision mold and die making. Check out this blog to discover how Electrical Discharge Machining can produce intricate and complex shapes with extreme accuracy, enabling exceptional quality products that meet even the most challenging specifications

Have you ever heard the saying “one false step leads to another”? It applies to all walks of life and is no different for the manufacturers on their shopfloors. And if you come from the field of precision engineering, you surely know that when making precision dies and molds even the slightest mistake can trigger a ‘domino effect’ that can ruin the entire project. That’s when it becomes imperative for manufacturers to employ advanced technologies like Electrical Discharge Machining (EDM) to carry out the process of making die and mold parts with complex shapes and unparalleled precision.

In this blog, we will explore in detail the indispensable role of EDM technology in precision mold & die making, and how this brilliant invention has revolutionized the industry by allowing manufacturers to produce components with extreme precision detail and tolerances that were once thought to be impossible.

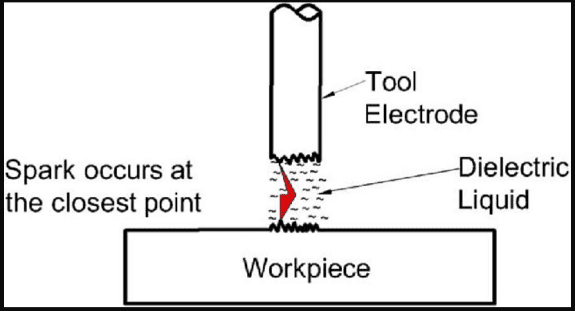

Understanding the principle of EDM technology

Electrical Discharge Machining or EDM works by using electrical sparks to erode a piece of metal to create a desired shape. The process involves bringing a metal electrode close to a part of the workpiece material allowing an electrical charge to pass through and erode the material by vaporizing tiny particles. This process can create complex shapes and intricate designs that would be difficult to produce using traditional cutting methods.

EDM technology is widely used in various industries, including aerospace, automotive, and medical, where precision and accuracy are of utmost importance. Overall, EDM technology has been enabling manufacturers to create complex shapes and designs with a high level of precision and accuracy.

CAD/CAM Software for EDM

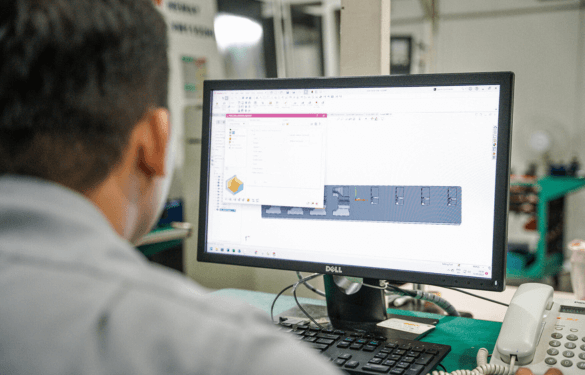

CAD/CAM software has a critical role to play across the entire process of precision die and mold making, from designing the part to the final machining steps. CAD/CAM software helps technicians simulate the machining process, allowing for adjustments and optimization before the actual machining begins.

This, in turn, ensures that the final product is not only precisely engineered with exceptional accuracy but also helps save valuable time and resources while minimizing the number of potential errors.

One has to understand that the CAD/CAM software does not directly communicate with the EDM machines. The EDM machine is programmed like all CNC (computer numeric control) machines and has its own hardwired software to process the CAD/CAM input and transfer it to the EDM machines. This way, the technicians can control the desired geometry and shape as per the CAD/CAM prototype as the machines do their job automatically and precisely.

With today’s EDM technology advancements, regardless of a technician’s skill level, even the most complicated shapes can still be perfectly done within a short amount of time, compared to conventional EDM control. Hence, it’s essential that modern manufacturers run up-to-date EDM machines to ensure the best possible results.

With CAD/CAM software for EDM, engineers can simulate the machining process, allowing for adjustments and optimization before the actual machining begins, saving time and resources while reducing the maximum errors. However, it’s essential that modern manufacturers are running ever-up-to-date EDM machines to ensure the best possible results.

Why EDM For Precision Mold and Die Making?

Not many of us are aware that the precision die and mold industry is actually behind the creation of the most complex components used in various fields such as automotive, aerospace, and medical. Therefore, it requires an incredible amount of attention to detail and accuracy, which is where EDM machining comes into play.

EDM offers an edge over conventional machining and can significantly impact the precision and efficiency of mold and die-making:

Making intricate die and mold shapes with ease

EDM technology can turn a manufacturer’s unique and complex requirements on the shapes and profiles into reality. EDM allows for greater precision and control when creating intricate geometries for molds and dies by using electrical discharges to remove material from the workpiece in a recurring sequence.

1. CNCTech

2. CAM Resources

CAM Resources has the right precision EDM, wire-cutting, grinding machines that can meet customer’s exact engineering specifications. As proof of the company’s excellent work in the industry, CAM Resources is the first foreign company to be awarded the Certificate of Science & Technology Enterprise by the People’s Committee of Long An Province.

CAM Resources also offers worldwide shipping of finished products in a timely and hassle-free fashion. It is one of the best choices for clients who are looking for surface grinding service that inherits foreign technology for a competitive pricing plan.

The special shapes, such as narrow slots and deep cavities, which in most cases, aren’t possible to make with traditional machining, can now be produced with EDM technology. Therefore, manufacturers can create unique and customized shapes with ease.

Cutting through hard and strong materials

The Electrical Discharge Machining (EDM) process is perfectly appropriate for cutting into hard metals such as steel and titanium as it doesn’t physically touch the workpiece. This makes it nearly impossible to damage the metal during cutting, something that often happens with traditional CNC machines. EDM machines tear through these materials with extreme precision, making them ideal for producing die and mold parts that demand absolute accuracy.

Incredibly efficient on the output

Also, EDM machines are extremely efficient, giving near-zero tolerances for the manufacturers, delivering precision as per engineering specifications, and shortening production times. Furthermore, EDM machines are highly cost-efficient, save resources and benefit modern manufacturing by optimizing the production processes.

Type of EDM machines used in die and mold making

There are different EDM machines used for different purposes, but primarily categorized into 2 types in the field of precision die and mold making: Electrode EDM and Wire-cut EDM.

Electrode EDM

Electrode EDM, or sinker EDM, works by utilizing a specially shaped electrode that is lowered into the workpiece. The electrode is typically made of graphite or copper and is designed to match the desired shape of the end product. The electrode is then brought very close to the workpiece, and a spark is created between them, eroding the metal in the form of tiny particles. This process continues until the desired shape has been achieved.

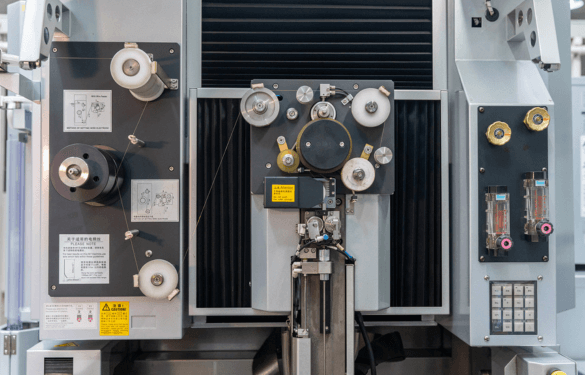

Wire-cut EDM

On the other hand, wire-cut EDM, also known as wire EDM, uses a thin wire made of copper or brass as a tool to cut the workpiece into the desired shape. The wire is once again brought very close to the workpiece, and a spark is created between them, cutting through the metal. As the wire passes through, it leaves behind a tiny gap that the dielectric fluid, usually deionized water, washes away. This process continues until the wire has cut through the entire workpiece to create the desired shape.

Choosing between EDM and Wire-cut EDM

EDM machines’ working principle is based on electrical sparks that form and shape metal workpieces. Although the two main types of EDM, electrode EDM, and wire-cut EDM, share the same working principle and some similar characteristics, a few important differences need to be considered before selecting the right method for your manufacturing process.

Electrode EDM is widely used for creating complex 3D shapes and intricate cavities that other cutting methods cannot match. This method has seen tremendous application in the aerospace, medical, and automotive industries for manufacturing parts with high accuracy. A few examples of electrode EDM applications include making dies and molds and tooling for plastic injection, forging, and stamping processes.

Wire-cut EDM is highly suitable for cutting two-dimensional shapes such as gears or flat plates with high accuracy. Besides metals, wire EDM is capable of cutting through conductive materials, including non-metals like ceramics and plastics. This versatility has made it a popular choice in manufacturing miniature and micro-sized components in a range of industries such as electronics, medical devices, and aerospace. Some of the typical applications of wire-cut EDM include creating fine blades for turbines, producing gears and bearings for machines, and making intricate medical devices, such as stents and catheters.

Maintenance and Safety of EDM Machines

Maintaining your EDM machines is crucial in precision die and mold making. It’s important to conduct regular maintenance to ensure that your machines are performing at their best. There are different maintenance procedures that you need to follow to keep your EDM machines in top shape. Some of these procedures include cleaning the machine regularly, changing the filters, and inspecting the wires and guides.

By following these procedures, you can extend the lifespan of your EDM machines, minimize downtime, and improve the quality of your output. Don’t wait until something goes wrong before you start paying attention to your machines. Take care of them regularly, and they will take care of your business.

State-of-the-art EDM technology services at CAM Resources

Without EDM machining, it’s merely impossible to create accurate molds and dies that can withstand the harsh conditions they are subjected to during their lifetime. The incredibly high level of precision required for these die and mold components make EDMs vital precision machines. It’s not an overstatement to say their importance will only continue to grow in the future and is a valuable investment for any manufacturer.

At CAM Resources, we offer cutting-edge EDM solutions to help you achieve unparalleled precision and the highest quality for your die and mold making process. Our EDM machines along with the latest CAD/CAM software and can deal with the most intricate details of your engineering specifications. Most of our EDM machines represent top brands made in Japan and built for delivering accuracy and customization.

The skilled workforce at CAM Resources knows what it takes to give you a perfect mold, and we strictly adhere to top-class machining and testing standards for your precision needs. Get in touch with us today and our English-speaking sales consultant will respond!