QUALITY

Precision on every single detail of the spec

OUR FOCUS ON QUALITY:

- Each detail is monitored by experienced technicians and assured of the tightest tolerances

- Continuously updating the latest technology for top-notch quality

- Skilled and attentive professionals in our quality department who prioritize customer satisfaction

- Meticulously oversee every stage of the process to guarantee that your parts meet your exact specifications.

STATE-OF-THE-ART testing EQUIPMENT:

Our quality control (QC) facility is fitted with state-of-the-art testing equipment, and this place ensures that only very accurate products are passed. That way, we ensure high-quality precision molds with accuracy that is near zero tolerance for our customer, before dispatch.

Hardness Testers +/-0.001 accuracy (Mitutoyo)

To accurately measure the depth or size indenting the surface

Measuring Microscopes +/- 0.002 accuracy (Sinown, Olympus)

To examine the end products, identify defects, and ensure standards

Height Gauges (Mikrometry)

To measure the height of the mold meant to serve the intended use.

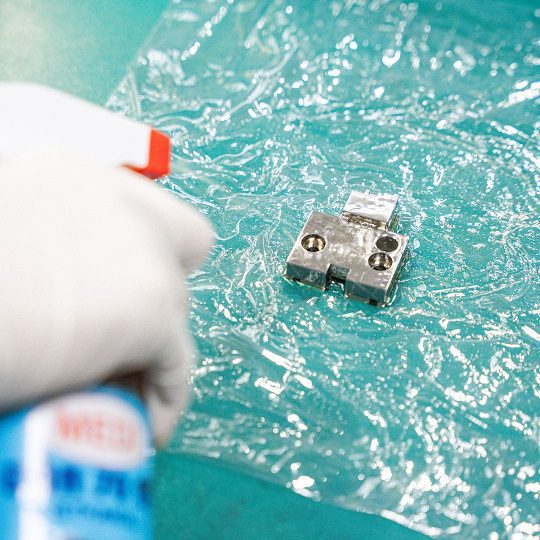

Packaging & Shipments

We take extra care of your precision tooling, mold, and die component shipments. Pre-packaging processes include demagnetizing, and rustproofing as well. We also do custom labeling on demand.

Upon receiving your blueprint, it takes less than 24 hours for our customer team to review it and get back with a quote. We value your time, take our commitment to delivery seriously, and strive to deliver high-quality precision molds and dies as per your specifications. Besides meeting the varied packaging standards of all countries, we exclusively work with our trusted delivery partner to ensure all your orders arrive at your doorstep on time.

Our Vietnam production facility is accredited by ISO9001-2015 Quality Management System (2023)