Discover how CAD/CAM software is used in the making of precision molds and how it may help you advance your production phases.

The manufacturing industry is an ever-evolving and competitive space that demands precision, accuracy, and cost-effectiveness. As a manufacturer, precision is the name of the game. Whether you’re working on intricate molds or complex mechanical designs, you need to be certain that your products meet the highest standards of quality and consistency. That’s where CAD/CAM software comes in, and it’s changing the game for manufacturers everywhere.

This software is a powerful tool that allows manufacturers to design, test, and refine precision molds with unprecedented accuracy and precision. With its intuitive interface and powerful simulation tools, CAD/CAM software is quickly becoming a must-have tool for manufacturers who want to stay ahead of the curve. In this blog post, we’ll explore the role of CAD/CAM software in testing precision molds and how it’s helping manufacturers achieve better results faster. So buckle up and get ready to learn how CAD/CAM software can help take your manufacturing game to the next level!

What is CAD/CAM software?

Precision mold making has come a long way since its early days of manual sculpting and casting. Nowadays, computer-aided design (CAD) software and computer-aided manufacturing (CAM) software have revolutionized the process by allowing for greater precision and efficiency in carving molds. The use of CAD/CAM software has been a game-changer in the production of molds for various products. This powerful tool streamlines the design process and enhances the efficiency of every stage of mold-making. By incorporating CAD/CAM software into the workflow, manufacturers can create perfect molds repeatedly, resulting in high-quality output. The role of CAD/CAM software cannot be overstated when it comes to crafting precise molds that are used to make products that we use every day.

One notable advantage of using this software is its customization capability. Customization is becoming increasingly vital as consumer preferences continue to evolve. With CAD/CAM software, companies can easily meet unique or highly specialized product requirements by simply feeding precise specifications into the computer. This leads to fewer errors during manufacturing and allows for faster delivery times while maintaining exceptional quality. It’s clear that CAD/CAM software plays an essential role in the production of precision molds.

Additionally, CAM software helps automate the manufacturing process by sending digital instructions directly to machines that cut and shape the mold materials. This eliminates the need for tedious manual labor and reduces the risk of mistakes that could ruin an entire batch of molds. As a result, this leads to faster production times and lowers the costs associated with creating molds.

In short, the role of CAD/CAM software in carving precision molds is critical in modern-day mold-making processes. By providing designers and manufacturers with more control over their designs, as well as automating the manufacturing process, CAD/CAM software has increased productivity, reduced errors, and created higher-quality products. As we move towards a world where consumers demand tailor-made products, the need for such advanced software will only grow. Manufacturers who invest in these technologies today are setting themselves up for success in tomorrow’s markets.

CAD/CAM software in designing precision molds

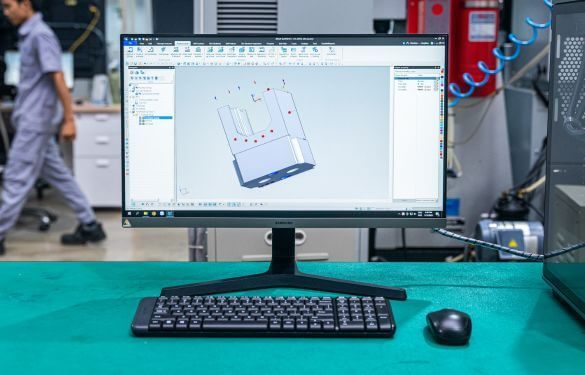

CAD/CAM software has revolutionized the art of precision mold engineering. It allows manufacturers to create complex and intricate designs with ease, reducing production time and increasing accuracy. CAD (computer-aided design) software enables designers to generate digital models that can be manipulated and refined until they achieve the desired result. CAM (computer-aided manufacturing) software takes this a step further by translating these digital models into precise instructions for machines to follow.

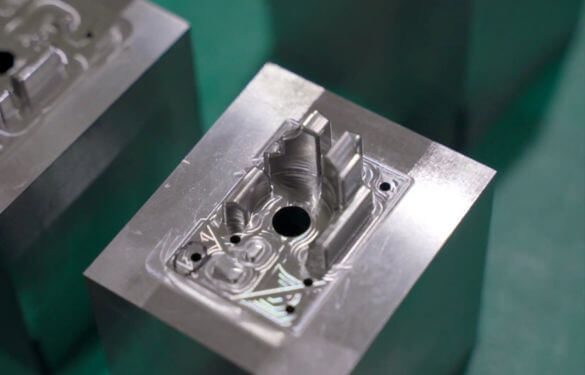

One of the key benefits of using CAD/CAM software is its ability to produce consistent results every time. Once a model has been created, it can be replicated over and over again without any variation in quality or accuracy. This is particularly important when producing molds for products such as automotive parts or medical devices, where even the slightest imperfection could have serious consequences. The use of CAD/CAM software also eliminates the need for manual labor, reducing human error and improving overall efficiency.

In addition to precision, CAD/CAM software also allows for greater creativity in mold design. The software provides designers with tools and features that make it easier to experiment with different shapes, sizes, and materials. This means that manufacturers can offer their customers more variety in product offerings while still maintaining high levels of quality control. Ultimately, the role of CAD/CAM software in carving precision molds cannot be overstated. Its impact on the manufacturing industry has been significant, and it continues to drive innovation and improvement in processes around the world.

CAD/CAM software in carving precision molds

Precision is key when it comes to molding, and in today’s world of manufacturing technology, CAD/CAM software plays a crucial role in ensuring that the molds produced meet high standards. These computer-aided design (CAD) and computer-aided manufacturing (CAM) tools have revolutionized the way manufacturers create molds by allowing them to create detailed designs on their computers before physically carving them out.

With CAD/CAM software, designers can easily sketch out intricate shapes and patterns with precision and accuracy, allowing for highly-detailed molds to be created with ease. This type of software also allows for adjustments to be made quickly and efficiently, meaning less time is wasted on physical trial-and-error iterations. Additionally, these programs offer increased flexibility since they can be used across various materials, including metals, plastics, and ceramics.

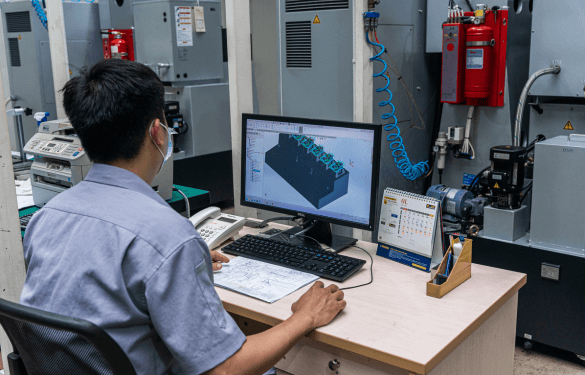

Moreover, using CAD/CAM software for CNC (computer numerical control) machines is now preferred when carving out precise molds with automated precision. . The level of accuracy achieved through these technological advancements ensures that molds are uniform and consistent, providing manufacturers with the ability to produce large quantities of products at a faster pace without sacrificing quality.

Overall, the use of CAD/CAM software has played an integral role in modern manufacturing processes. From automotive parts to consumer electronics, this software has allowed companies to save valuable time and resources while producing high-quality precision molds. As technology continues to evolve and improve, we can only expect further innovations to come from the integration of CAD/CAM software into production lines.

CAD/CAM software in testing precision molds

1. We strive for "zero"

As a manufacturer, you understand the importance of precision molds in the production process. Every detail matters, from the design to the testing phase, and any error can result in costly delays and lost revenue. To ensure that your molds meet the highest standards, you need a reliable tool that can help you test them with accuracy and efficiency. This is where CAD/CAM software comes into play.

2. We have what it takes

CAD/CAM software has revolutionized the manufacturing industry, providing a range of benefits that make the production process smoother and more efficient. Among these benefits is the ability to test precision molds with unparalleled precision and speed. Testing precision molds with CAD/CAM software can save a lot of time and money in the manufacturing process. By using this software, we can simulate the molding process and check for any potential errors before we even start making the mold. It’s amazing how precise this technology is!

We can identify any defects or potential issues and make necessary adjustments before we even start the manufacturing process. This means we can catch any problems early on and avoid costly mistakes down the line. It’s a game-changer for the industry and ensures that we can produce high-quality molds with minimal errors.

To sum up, the role of CAD/CAM software in carving precision molds cannot be overstated. It is an essential tool for any industry that requires accurate and consistent product manufacturing. The benefits of using these software programs include improved design capabilities, reduced errors, increased efficiency, and the ability to customize molds to meet individual needs. As technology continues to advance, we can expect further developments in the field of mold-making, making it easier than ever to produce high-quality products consistently.

3. The skilled touch of operators

Besides frequently maintained tools, Cam Resources constantly train and update technicians to stay ahead of their game. Years of experience within the precision mold industry keep personnel alert and motivated to solve complications that arise during the process. At Cam Resources, we rely on the combination of both humans and machines to ensure top-notch quality for your precision molds and tools.

Conclusion

In today’s world, precision is key. In every field of work, accuracy, and attention to detail are essential for success. This is especially true when it comes to the manufacturing industry, where even the slightest deviation from specifications can result in costly mistakes. That’s why the use of CAD/CAM software has become such a vital tool for creating precision molds.

In addition to its practical applications, CAD/CAM technology has also opened up new avenues for creativity and innovation. With the ability to quickly and accurately produce complex shapes and geometries, manufacturers have more freedom than ever before to experiment with unconventional designs. And as this technology continues to improve, we can expect even greater precision and versatility in the future. So whether you’re designing the latest smartphone or crafting intricate automotive parts, CAD/CAM software is an indispensable tool for achieving excellence in modern manufacturing.

At CAM Resources, we understand the importance of precision molds in the manufacturing industry. We know that every detail counts and even the smallest imperfection can have serious consequences for our clients. That’s why we utilize the latest CAD/CAM software to design and create custom molds that meet the highest standards of accuracy and quality. So put your trust in CAM Resources, as we are committed to staying on the cutting edge of these advancements to ensure our clients always receive the best possible solutions for their needs.

Get your quote from CAM Resources here.